How to Choose the Best Injection Molded Parts for Your Project Needs

In the fast-paced world of manufacturing, choosing the right components for your project is crucial to success. Injection molded parts represent a significant portion of the market, with reports indicating that the global injection molded plastics market was valued at approximately $300 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of over 5% through 2027. This growth underscores the demand for precision-engineered components that meet specific requirements across various industries, including automotive, consumer goods, and medical equipment.

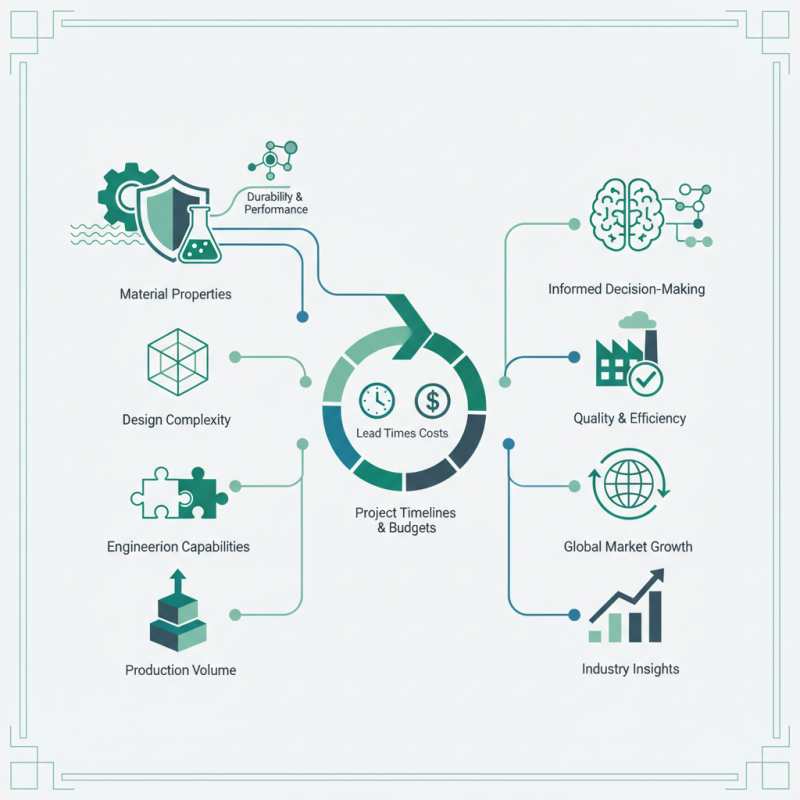

When selecting the best injection molded parts for your project needs, it is essential to consider factors such as material properties, design complexity, and production volume. Research indicates that over 60% of manufacturers prioritize the durability and performance of materials in their selection process, highlighting the critical role of engineering in effective design. Additionally, understanding the production capabilities, lead times, and costs associated with injection molding can significantly impact project timelines and budgets, further emphasizing the importance of informed decision-making in this crucial stage of product development. By leveraging industry insights, manufacturers can optimize their choices for injection molded parts, ensuring quality and efficiency in their final products.

Understanding Injection Molding: An Overview of the Process

Injection molding is a widely utilized manufacturing process that plays a crucial role in producing a variety of plastic parts for diverse industries. Understanding this process is key for making informed decisions regarding the best injection molded parts for specific project needs. The core of injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired shape. According to the 2022 Global Market Insights report, the injection molding market is projected to exceed $450 billion by 2026, demonstrating the method's significance in manufacturing today.

The efficiency and precision of injection molding make it an attractive option for producing complex geometries and high volumes. Industry studies indicate that it allows for rapid production cycles, with some machines capable of completing a cycle in as little as 15 seconds. Furthermore, advancements in technology, such as the implementation of computer-aided design (CAD) and simulation software, enhance the development process, reducing time and costs associated with prototyping. The ability to achieve tight tolerances, often within 0.001 inches, is another compelling reason to consider injection molded parts for intricate designs and high-performance applications. Understanding these aspects helps project managers and engineers choose the most suitable components to meet their operational demands.

Injection Molded Parts Production by Material Type

This bar chart illustrates the production volume of different types of injection molded parts by material. It highlights the prevalence of thermoplastics in the industry, followed by thermosetting plastics, elastomers, and biodegradable plastics.

Identifying Your Project Requirements for Injection Molded Parts

When embarking on a project that requires injection molded parts, the first step is to thoroughly identify your project requirements. Understanding the specific application and environment in which the parts will be used is crucial. For instance, a report by MarketsandMarkets indicates that the global injection molded plastics market is poised to reach $320 billion by 2025, largely driven by the automotive and consumer goods sectors. This underscores the importance of choosing the right materials and designs tailored to your application, whether you require high-impact resistance, thermal stability, or specific aesthetic qualities.

Another critical consideration is the production volume needed. According to a study by Mordor Intelligence, high-volume production can lead to significantly lower per-unit costs due to economies of scale. As such, accurately estimating the required quantity of parts can influence material selection and tooling processes. Additionally, understanding your lead times and delivery schedules can help in selecting the appropriate manufacturing partner that aligns with your project timeline. Evaluating these requirements not only streamlines the selection process but also enhances the overall efficiency and success of your project.

Factors to Consider When Selecting Materials for Molding

When selecting materials for injection molded parts, several critical factors must be taken into account to ensure that the final product meets project specifications and performance standards. One primary consideration is the mechanical properties required for the application. According to a 2020 report by Grand View Research, materials such as ABS and polycarbonate are often favored in industries requiring high impact resistance and durability. The tensile strength, elongation at break, and hardness of the material directly influence the part's functionality, making it essential to reference detailed material data sheets during the selection process.

Another key factor is thermal stability, especially in applications exposed to variable temperature ranges. The same Grand View Research report highlights that materials like nylon and polyester are preferred in automotive and electrical components due to their superior heat resistance and dimensional stability. It is crucial to analyze the thermal properties of the material, including glass transition temperature and melting point, to ensure that the parts will perform reliably under the intended operating conditions. By carefully considering these factors, engineers can select the most suitable materials for injection molding that will optimize both performance and cost-efficiency.

Evaluating Design Specifications for Optimal Performance

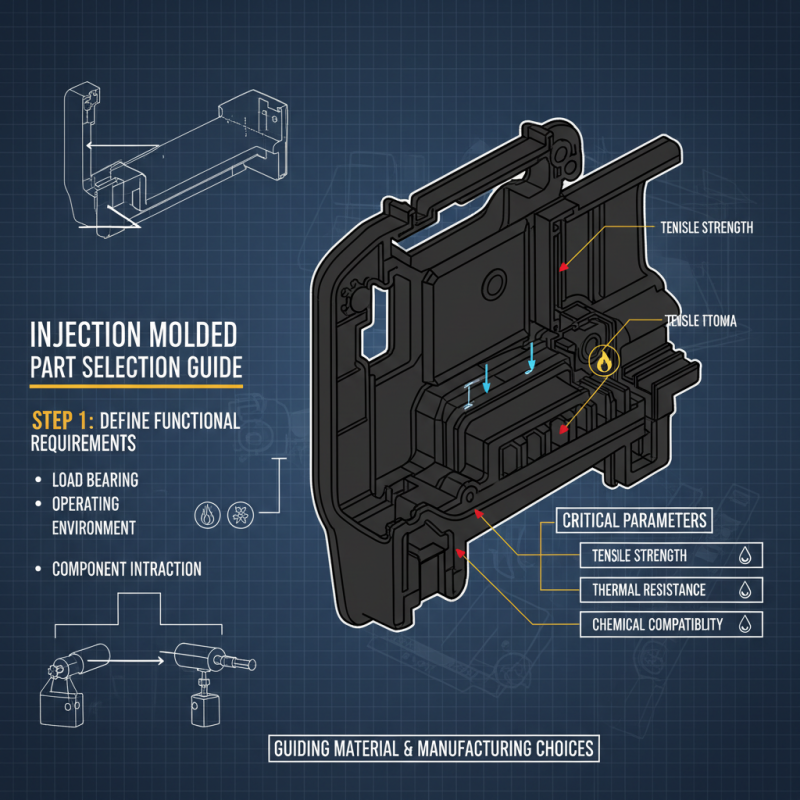

When selecting injection molded parts for any project, it’s crucial to evaluate the design specifications to ensure optimal performance. The first step in this process is to clearly define the functional requirements of the part. Understanding the load it will bear, the environment it will operate in, and its interaction with other components will help shape the design. Consideration of factors such as tensile strength, thermal resistance, and chemical compatibility is essential. These parameters will guide you in choosing the right materials and manufacturing techniques that align with your project goals.

Additionally, the geometry of the part plays a significant role in its performance. Complex designs may require advanced molding techniques, while simpler shapes may be easier to produce and more cost-effective. It’s also important to assess how the design affects the injection molding process itself, such as gating, cooling, and the potential for defects like warping or shrinkage. By thoroughly evaluating all these design specifications, you can not only meet the practical demands of your project but also optimize the manufacturability of the parts, resulting in better quality and efficiency in production.

Assessing Manufacturer Capabilities and Reliability for Your Needs

When selecting injection molded parts for your project, it's critical to evaluate the capabilities and reliability of the manufacturer. A proficient manufacturer should have experience in your specific industry and be equipped with the latest technology to produce high-quality parts. Assessing their production capacity and turnaround times can also provide insight into their reliability. A manufacturer that can swiftly adapt to your changing needs will enhance the flexibility of your project.

**Tips:** When communicating with potential manufacturers, ask for samples of their previous work. This will not only allow you to gauge the quality of their products but also to determine if their work aligns with your project requirements. Additionally, checking for certifications or industry-standard compliance can serve as an assurance of their reliability.

It's also advisable to inquire about their sourcing materials and production processes. A transparent approach indicates a responsible manufacturer committed to quality control and sustainability practices. Engaging in discussions about their troubleshooting mechanisms can further illuminate how they handle challenges, ensuring that you partner with a dependable supplier who can support your project effectively.

How to Choose the Best Injection Molded Parts for Your Project Needs

| Criteria | Description | Rating (1-5) | Notes |

|---|---|---|---|

| Material Selection | Evaluate the variety of materials available for injection molding. | 4 | Polypropylene and ABS are commonly available. |

| Production Capacity | Assess the manufacturer’s ability to meet project volume requirements. | 5 | Can handle large and small batch sizes. |

| Quality Assurance | Examine the quality control processes in place. | 4 | ISO certifications and regular audits conducted. |

| Lead Times | Consider the time it takes from order to delivery. | 3 | Production can take up to 6 weeks. |

| Customer Support | Look into the responsiveness and support offered. | 5 | 24/7 support available, knowledgeable staff. |

| Cost Competitiveness | Determine pricing structures and value for money. | 4 | Competitive pricing compared to industry standards. |

Related Posts

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

-

How to Choose the Right Injection Molded Parts for Your Project

-

10 Essential Tips for Designing Efficient Injection Molded Parts