How to Choose the Right Injection Molded Parts for Your Project

Choosing the right injection molded parts is a critical step in ensuring the success of any manufacturing project. As industry expert Dr. Emily Carter once said, "The precision and quality of injection molded parts can make or break a project." With the numerous options available in the market, understanding how to select the appropriate materials and specifications is essential for optimizing performance and achieving cost-efficiency.

Injection molded parts are pivotal in various applications, from consumer goods to automotive components. They provide a level of design flexibility and complexity that is unmatched by other manufacturing processes. However, the decision-making process can be daunting, given the multitude of parameters that need consideration, such as material choice, production volume, and lead times. By understanding the nuances of injection molding, engineers and designers can make informed choices that align with their project requirements.

In this article, we will delve into the key factors that influence the selection of injection molded parts, offering insights and practical guidance to help you navigate this critical aspect of your project. Whether you are looking to reduce costs, enhance product durability, or streamline production, knowing how to choose the right injection molded parts is vital for achieving your goals.

Understanding Injection Molding and Its Applications

Injection molding is a highly versatile manufacturing process that is employed to produce a wide array of components across various industries, including automotive, consumer goods, and medical devices. According to a report by MarketsandMarkets, the global injection molding market size was valued at approximately $200 billion in 2020 and is projected to reach over $300 billion by 2026. This growth is driven by the increasing demand for lightweight and durable materials that can be molded into complex shapes, which traditional manufacturing methods often struggle to achieve.

Understanding the intricacies of injection molding can significantly enhance project outcomes. It begins with selecting the right materials, as different thermoplastics and thermosets offer unique properties such as strength, flexibility, and resistance to heat and chemicals. Additionally, the design of the mold itself plays a critical role; factors such as wall thickness, draft angle, and gate location must be carefully considered to ensure efficient production and minimize defects.

Tips:

- Always prototype your designs using 3D printing to identify potential issues before committing to injection molded parts.

- Consult with experienced engineers about the selection of materials, as they can provide insights on cost-effectiveness and suitability for specific applications.

- Consider the lifecycle of the part you are producing and factor in sustainability; biodegradable plastics and recyclable materials are becoming increasingly popular in the industry.

Key Factors to Consider When Selecting Injection Molded Parts

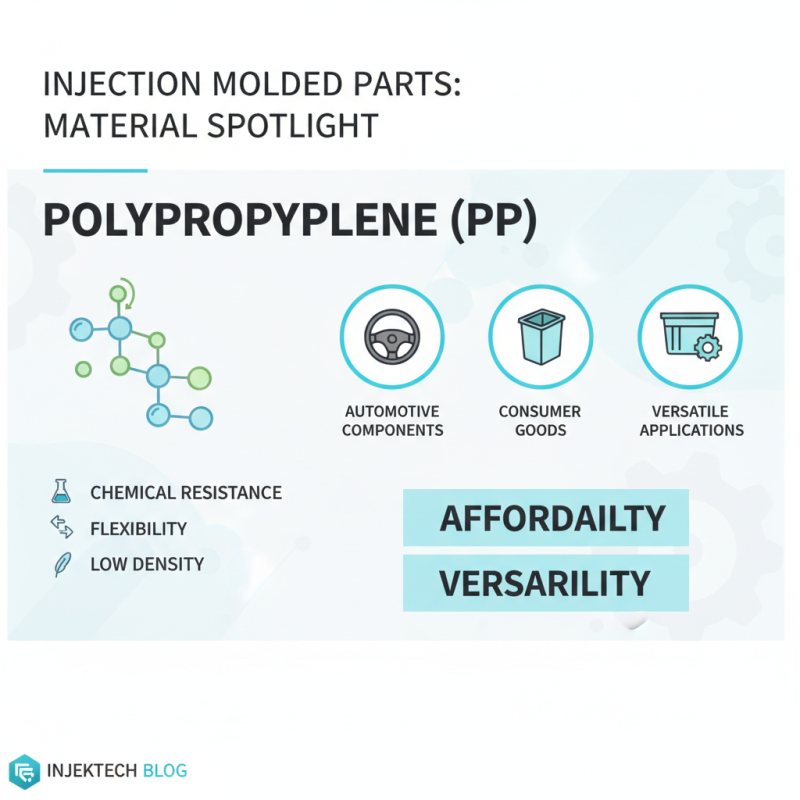

When selecting injection molded parts for a project, several key factors must be taken into account to ensure optimal performance and cost-effectiveness. Firstly, material selection plays a critical role. According to the Plastics Industry Association, more than 60% of all injection molded products utilize thermoplastics, which offer benefits in terms of durability and versatility. Understanding the mechanical properties, thermal stability, and chemical resistance of these materials is essential for matching them to specific application requirements. For instance, Polypropylene (PP) is favored for its lightweight nature and resistance to chemicals, making it a top choice for packaging and automotive applications.

Another important consideration is the design and complexity of the molded parts. The Association for Manufacturing Technology highlights that approximately 80% of a product’s cost is determined during the design phase. Optimizing the design for manufacturability can significantly reduce production costs and lead times. Factors such as wall thickness, part geometry, and tolerance levels must be carefully evaluated to avoid issues during the molding process. Additionally, employing mold flow analysis can predict how the material will fill the mold, ensuring that potential defects are identified and mitigated early in the design process. This proactive approach not only enhances quality but also contributes to efficient production cycles and reduced waste.

How to Choose the Right Injection Molded Parts for Your Project - Key Factors to Consider When Selecting Injection Molded Parts

| Factor | Description | Importance Level |

|---|---|---|

| Material Selection | Choosing the right polymer based on application requirements like strength and heat resistance. | High |

| Tolerance Requirements | Understanding the precision needed for fitting parts together. | Medium |

| Production Volume | Estimates of how many parts are needed can affect molding options. | High |

| Design Complexity | Consideration of how intricate the design will affect mold making and costs. | Medium |

| Finishing Options | The surface finish and treatment necessary for the specific application. | Low |

| Cost Constraints | Budget limitations that could affect material and production choices. | High |

Materials Commonly Used in Injection Molded Parts

When selecting materials for injection molded parts, it is crucial to understand the characteristics and applications of common materials used in the industry. One of the most popular materials is polypropylene (PP), known for its excellent chemical resistance, flexibility, and low density. It is widely used for various applications, from automotive components to consumer goods, due to its affordability and versatility.

Another commonly used material is acrylonitrile butadiene styrene (ABS). This thermoplastic is favored for its impact resistance and durability, making it suitable for parts that require strength and aesthetic appeal, such as housings and toys. Polyethylene (PE), including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), is also frequently chosen for its toughness, lightweight nature, and resistance to moisture, making it ideal for packaging and everyday consumer products. Understanding the properties of these materials ensures that the right choice is made for specific project requirements.

Analyzing Design Specifications for Injection Molded Components

When selecting injection molded parts for a project, analyzing the design specifications is crucial to ensure functionality and cost-effectiveness. Key factors such as material selection, dimensional tolerances, and part complexity play a significant role in the overall performance of molded components. According to a recent report by Grand View Research, the global injection molding market is expected to reach $400 billion by 2027, driven by advances in design capabilities and technology. Engineers must focus on precise specifications to optimize these factors while minimizing production costs.

One of the critical aspects of design specifications is the selection of appropriate materials. Various polymers, such as polypropylene, polystyrene, and polycarbonate, have unique properties that influence their application. For instance, polycarbonate offers high impact resistance and optical clarity, making it suitable for components requiring durability and transparency. A study from Markets and Markets indicates that high-performance plastics are projected to grow at a CAGR of 7.1% from 2021 to 2026, reflecting the increasing demand for innovative and specialized injection molded parts. Therefore, a comprehensive understanding of materials and their properties is essential for achieving the desired performance and longevity in the final product.

Material Selection for Injection Molded Parts

Evaluating Manufacturers for Quality and Reliability in Production

When selecting injection molded parts for a project, evaluating manufacturers for quality and reliability is crucial. A reputable manufacturer should demonstrate a commitment to quality through certifications and adherence to industry standards. Look for companies that implement rigorous quality control processes, including regular inspections and testing of their products. Such measures ensure that the parts produced are consistent and meet the specifications required for successful integration into your project.

In addition to quality, reliability in production is another key factor to consider. Assess the manufacturer's capacity to meet deadlines and their track record of fulfilling orders on time. Engaging with references and reviews from previous clients can provide insight into their operational efficiency. Furthermore, understanding their production capabilities and flexibility in accommodating changes during the manufacturing process can help you make an informed decision. Selecting a manufacturer that prioritizes both quality and reliability will not only enhance the success of your project but also establish a sound partnership for future endeavors.

Related Posts

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Revolutionizing Manufacturing: The Future of Plastic Injection Molding Technologies

-

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

-

10 Essential Tips for Designing Efficient Injection Molded Parts

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

-

Exploring the Versatility of PVC Sheets: Innovative Applications You Didn't Know About