2025 Top PVC Material Innovations for Sustainable Construction and Design

In recent years, the construction and design industries have increasingly turned their focus towards sustainable practices, driven by the urgent need to minimize environmental impact. Among the various materials that have gained prominence in this movement, PVC material has emerged as a significant player due to its versatility, durability, and recyclability. As we look ahead to 2025, innovations in PVC material are set to reshape the landscape of sustainable construction and design, offering solutions that are both eco-friendly and efficient.

The upcoming advancements in PVC material are not just about enhancing functionality but also about integrating sustainability into every step of the production process. From improved recycling techniques to the development of bio-based additives, these innovations are designed to lessen carbon footprints and promote a circular economy within the industry. As architects and builders increasingly embrace these cutting-edge PVC solutions, the potential for creating spaces that harmoniously blend environmental responsibility with aesthetic appeal becomes more attainable than ever.

As we explore the top PVC material innovations of 2025, it is crucial to highlight their role in achieving sustainability goals while addressing the growing demand for resilient and high-performance building materials. This discussion will delve into the transformative properties of these innovations and how they can effectively contribute to greener construction practices, paving the way for a more sustainable future in design and architecture.

Read more »

By:Sophie - December 8, 2025

By:Sophie - December 8, 2025

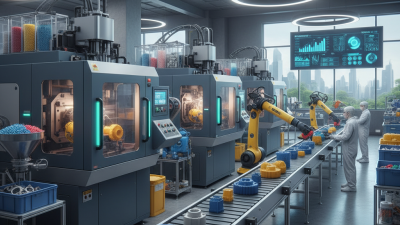

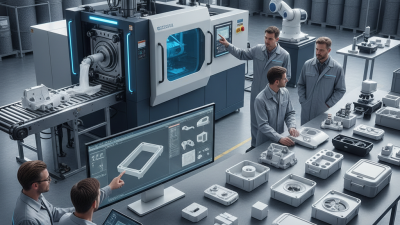

Top 10 Essential Injection Molding Tooling Techniques for Efficient Production

Injection molding tooling plays a crucial role in the efficiency and effectiveness of the manufacturing process within various industries. As companies continue to seek innovative ways to enhance productivity while maintaining high-quality standards, understanding the essential techniques in injection molding tooling becomes increasingly vital. These techniques not only optimize production speed but also ensure precision in the final products, reducing waste and costs associated with defects.

In this article, we will delve into the top 10 essential injection molding tooling techniques that can significantly impact production outcomes. From the initial design phase to the final execution of molds, each technique will be explored in detail, highlighting best practices and strategies that manufacturers can implement. By mastering these techniques, businesses can streamline their operations, improve turnaround times, and ultimately achieve a competitive edge in the marketplace. Whether you are new to injection molding or looking to refine your existing processes, this guide aims to provide valuable insights that can lead to efficient and successful production outcomes.

Read more »

By:Lucas - December 5, 2025

By:Lucas - December 5, 2025

Top Uses of Poly Plastic in Everyday Life and Its Environmental Impact

Poly plastic has become an integral part of our daily lives, offering convenience and functionality in a variety of forms. From packaging materials to household items, the versatility of poly plastic is unmatched, allowing it to meet the diverse needs of consumers in a fast-paced world. Products made from poly plastic are not only lightweight and durable but also adaptable, making them a popular choice in industries ranging from food service to fashion. As we explore the top uses of poly plastic in everyday life, we will discover how these materials have revolutionized the way we live, shop, and interact with our environment.

However, the widespread use of poly plastic brings with it significant environmental challenges. The durability that makes poly plastic so useful also contributes to its persistence in the environment, leading to pollution and waste management issues. As poly plastic products often end up in landfills or oceans, they pose threats to wildlife and ecosystems. Therefore, it is crucial to examine the balance between the practical benefits of poly plastic and its environmental impact. This exploration will help us understand not only how we can utilize poly plastic effectively but also how we can mitigate its detrimental effects on our planet.

Read more »

By:Sophie - December 4, 2025

By:Sophie - December 4, 2025

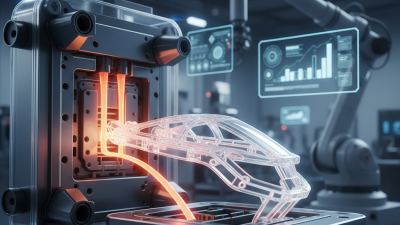

2025 Top 10 Low Cost Injection Molding Solutions for Efficient Manufacturing

In the rapidly evolving landscape of manufacturing, businesses are increasingly turning to low cost injection molding as a means to optimize production without compromising on quality. According to a recent report by MarketsandMarkets, the global injection molding market is expected to reach $388.3 billion by 2025, highlighting the growing demand for cost-effective solutions that cater to various industries. This surge in popularity underscores the importance of identifying and adopting innovative approaches to injection molding that can enhance efficiency while keeping costs manageable.

Industry expert Dr. Michael Carter, a leading figure in polymer processing technology, emphasizes the potential of low cost injection molding: “The future of manufacturing lies in our ability to balance affordability with sustainability, and low cost injection molding is a key driver in achieving this goal.” As manufacturers face increasing pressure to streamline operations and reduce expenses, exploring the Top 10 low cost injection molding solutions for 2025 becomes essential for staying competitive. With advancements in materials, machinery, and processes, companies can leverage these innovations to meet their production needs effectively while maintaining a firm grip on costs.

Read more »

By:Lucas - December 2, 2025

By:Lucas - December 2, 2025

10 Essential Tips for Designing Efficient Injection Molded Parts

In the rapidly evolving manufacturing landscape, injection molded parts have become a cornerstone in various industries, ranging from automotive to consumer goods. According to recent industry reports, the global injection molding market was valued at approximately $234 billion in 2020 and is projected to reach $360 billion by 2027, reflecting a substantial compound annual growth rate (CAGR) of over 6%. This growth signifies the escalating demand for high-quality, efficient molded components that meet stringent performance and cost criteria.

To harness the full potential of injection molding, designers must focus on optimizing their design processes. Effective design not only enhances product performance but also plays a crucial role in minimizing waste and reducing production costs. Studies indicate that up to 70% of product costs can be determined at the design stage, underscoring the importance of thoughtful design strategies in the injection molding process. By implementing best practices and innovative techniques, companies can significantly improve the manufacturability and sustainability of their injection molded parts, thereby achieving a competitive edge in the marketplace.

This article presents 10 essential tips for designing efficient injection molded parts, aimed at guiding engineers and designers to maximize the advantages of this versatile manufacturing method.

Read more »

By:Sophie - November 30, 2025

By:Sophie - November 30, 2025

How to Design for Injection Molding: Essential Tips for Success

In the ever-evolving landscape of manufacturing, "design for injection molding" has emerged as a crucial consideration for engineers and product developers seeking to optimize production efficiency and product quality. According to a report from MarketsandMarkets, the global injection molding market is expected to reach $350 billion by 2025, driven by increasing demand across several sectors, including automotive, consumer goods, and healthcare. This growth underscores the importance of understanding the intricacies of design specific to injection molding processes, which can significantly impact both production costs and timelines.

To achieve successful outcomes, it is vital to adhere to essential design principles that cater to the unique characteristics of injection molding. Factors such as material selection, wall thickness, and mold design play a pivotal role in ensuring that the final product meets both aesthetic and functional requirements. The American Society of Mechanical Engineers (ASME) highlights that inefficient design practices can lead to common pitfalls, such as increased cycle times and post-production defects, which can ultimately affect profitability. By prioritizing a well-informed design approach, manufacturers can enhance not only the resilience and performance of their products but also their competitive edge in a saturated market.

Read more »

By:Lucas - November 29, 2025

By:Lucas - November 29, 2025

Unlocking Innovation: The Future of Design for Injection Molding in 2025

As we approach 2025, the realm of design for injection molding is poised for transformative changes that will redefine the standards of efficiency, sustainability, and creativity within the manufacturing industry. With rapid advancements in technology, especially in areas such as automation, materials science, and computer-aided design, innovative methodologies are emerging that enhance the design process, streamline production, and reduce environmental impact. This evolution requires designers and engineers to re-evaluate traditional practices and embrace new strategies that not only accommodate the complexities of modern products but also align with the expectations of eco-conscious consumers.

The future of design for injection molding will likely incorporate intelligent design principles, where the use of data analytics and machine learning streamlines production processes and optimizes designs for both functionality and manufacturability. Moreover, the integration of advanced materials will expand the possibilities for creating more durable, lightweight, and sustainable parts. As we explore the “2025 How to” genres related to injection molding, it becomes evident that a proactive approach towards innovation and collaboration will empower industry players to overcome challenges and seize opportunities, leading to a new era of design excellence.

Read more »

By:Ethan - November 27, 2025

By:Ethan - November 27, 2025

2025 Top 10 Innovations in Injection Moulding Process: Boost Efficiency by 30%+

The injection moulding process has long been a cornerstone of the manufacturing industry, enabling the production of complex shapes with high efficiency and precision. As we look towards 2025, significant advancements in this area promise not only to enhance productivity but also to drive down costs. According to a report by Mordor Intelligence, the global injection moulding market is expected to reach USD 367.46 billion by 2026, growing at a CAGR of 3.5%. This growth reflects an increasing demand for innovative techniques that can streamline operations and minimize waste.

The upcoming decade is poised to be transformative for the injection moulding process, with innovations such as advanced materials, automation, and artificial intelligence set to redefine traditional methodologies. A recent study by the Association for Manufacturing Technology revealed that businesses adopting these innovations could enhance their operational efficiency by over 30%. Such improvements are vital not only for maintaining competitive advantage but also for meeting rising environmental regulations and customer demands for sustainability in manufacturing practices.

As we explore the 2025 top ten innovations in the injection moulding process, it is crucial to understand how these developments will not only alter production methods but also yield quantifiable benefits that align with the industry's future goals of efficiency and sustainability.

Read more »

By:Ethan - November 25, 2025

By:Ethan - November 25, 2025

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

Injection molding has revolutionized the manufacturing landscape, offering unparalleled efficiency and precision in producing a wide variety of components. As industries strive to meet the ever-increasing demand for high-quality products, understanding the benefits of injection molding becomes crucial. This versatile technique not only streamlines production processes but also enhances product design flexibility, significantly reducing time to market.

One of the most compelling advantages of injection molding lies in its ability to produce complex geometries and tight tolerances with minimal waste. Manufacturers can leverage this technology to create intricate parts that would be difficult, if not impossible, to achieve through traditional manufacturing methods. Furthermore, the scalable nature of injection molding allows for high-volume production, making it an attractive option for businesses looking to optimize their workflow and reduce per-unit costs.

In this article, we will delve into the top ten benefits of injection molding that contribute to improved manufacturing efficiency. From reduced cycle times to enhanced material utilization, understanding these advantages will empower manufacturers to make informed decisions that drive competitiveness and innovation in their respective fields.

Read more »

By:Sophie - November 23, 2025

By:Sophie - November 23, 2025

10 Best PVC Material Products for Durable Home and Garden Solutions

In the quest for durable and versatile solutions for home and garden, the use of PVC material has gained remarkable popularity. This synthetic plastic polymer is not only lightweight and resistant to water and chemicals but also offers exceptional durability, making it an ideal choice for a wide range of applications. From outdoor furniture to gardening tools, PVC products have become an indispensable component in enhancing both the functionality and aesthetics of our living spaces.

As homeowners and gardening enthusiasts increasingly seek reliability and longevity in their purchases, the demand for quality PVC material products continues to rise. The beauty of PVC lies in its adaptability; it can be molded into various shapes and designs, catering to different tastes and requirements. In this guide, we will explore the ten best PVC material products available on the market today, each uniquely designed to provide robust solutions for your home and garden needs. Whether you are looking to spruce up your outdoor space or streamline your indoor organization, these PVC products offer a perfect blend of style, sustainability, and strength.

Read more »

By:Sophie - November 22, 2025

By:Sophie - November 22, 2025

Top 10 Benefits of Using Plastic Caps for Packaging and Their Market Growth Insights

In the ever-evolving world of packaging, plastic caps have emerged as a crucial component, offering numerous benefits that can significantly enhance product integrity and consumer satisfaction. According to industry expert Dr. Emily Harrison, a leading figure in sustainable packaging solutions, “The versatility and reliability of plastic caps make them indispensable in modern packaging, balancing functionality with eco-friendliness.” As companies seek to adapt to market demands and improve their competitive edge, understanding the advantages of using plastic caps is essential.

From cost-effectiveness to superior sealing capabilities, plastic caps offer a myriad of benefits that not only enhance packaging efficiency but also contribute to brand perception. The growth of the plastic cap market underscores the increasing recognition of these advantages among manufacturers and consumers alike. Recent trends highlight a growing emphasis on sustainability, as companies strive to meet environmental standards while still providing high-quality packaging solutions. This introduction paves the way to explore the top ten benefits of plastic caps for packaging, as well as insights into the market growth that positions them at the forefront of the packaging industry.

Read more »

By:Sophie - November 20, 2025

By:Sophie - November 20, 2025

Innovative Techniques for Optimizing Design for Injection Molding in Modern Manufacturing

In the realm of modern manufacturing, the significance of "design for injection molding" cannot be overstated. As industries evolve, optimizing injection molding design has become essential for enhancing efficiency, reducing costs, and improving product quality. According to renowned expert Dr. John Matthews, a leading figure in injection molding technology, “Effective design for injection molding not only streamlines production but also creates innovative products that meet today's demanding market standards.” His insights highlight the critical role that innovative techniques play in refining the design process.

As manufacturers strive to remain competitive, understanding the intricate relationship between design and production is paramount. Modern innovations—ranging from advanced software simulations to material science breakthroughs—are reshaping how products are conceived and manufactured. By integrating these techniques, designers can anticipate potential challenges and develop solutions that integrate seamlessly into the injection molding process.

Ultimately, the pursuit of excellence in design for injection molding is a continuing journey, necessitating collaboration between engineers, designers, and manufacturing specialists. With the ongoing advancements in technology and materials, the future of injection molding design looks promising. Embracing these innovative techniques will not only enhance operational efficiency but also redefine product possibilities in the ever-evolving manufacturing landscape.

Read more »

By:Sophie - November 19, 2025

By:Sophie - November 19, 2025

Discovering the Secrets of Low Cost Injection Molding for Beginners

In today's competitive manufacturing landscape, "low cost injection molding" has emerged as a game-changer for startups and small businesses looking to optimize their production processes without sacrificing quality. According to a report by Allied Market Research, the global injection molding market is projected to reach $391.3 billion by 2028, growing at a CAGR of 4.5%. This trend highlights the increasing accessibility of advanced molding technologies for beginners eager to enter the market. With the right insights and tips, even those with limited capital can leverage low-cost methodologies to create high-quality prototypes and products. The secret lies in understanding the nuances of material selection, mold design, and production efficiency—all critical factors in minimizing costs while maximizing output. As we delve into the essential strategies for effective low-cost injection molding, aspiring manufacturers will gain the knowledge needed to thrive in this dynamic industry.

Read more »

By:Sophie - November 14, 2025

By:Sophie - November 14, 2025

Exploring the Versatility of PVC Sheets: Innovative Applications You Didn't Know About

In recent years, the versatility of PVC sheets has gained significant attention across various industries, showcasing innovative applications that extend far beyond traditional uses. According to a report by Grand View Research, the global market for PVC sheets is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028, driven by their lightweight, durable, and moisture-resistant properties. These sheets are increasingly being adopted in areas such as architecture, signage, and even medical applications, where their adaptability brings substantial benefits. As industries continue to seek cost-effective and reliable materials, it is essential to explore the myriad of ways PVC sheets can be utilized, revealing approaches and innovations that many professionals may not yet be aware of. This article delves into the extensive and sometimes surprising applications of PVC sheets, illustrating their integral role in modern manufacturing and design.

Read more »

By:Lucas - November 12, 2025

By:Lucas - November 12, 2025

Exploring the Versatility of PVC Material: Applications, Benefits, and Environmental Impact

PVC material, known for its exceptional versatility and durability, has become a cornerstone in various industries, ranging from construction to healthcare. According to a report by the Plastics Industry Association, the global demand for PVC is expected to reach 42 million metric tons by 2025, reflecting its growing significance in modern applications. This synthetic polymer not only offers an excellent balance of performance and cost-effectiveness but also contributes to sustainability initiatives, as recycling processes for PVC are becoming increasingly efficient. Products made from PVC material, such as pipes, flooring, and medical devices, showcase its adaptability while meeting regulatory standards for safety. As industries continue to seek innovative solutions that align with environmental goals, understanding the applications, benefits, and impacts of PVC material is crucial for paving the way towards a more sustainable future.

Read more »

By:Ethan - November 11, 2025

By:Ethan - November 11, 2025