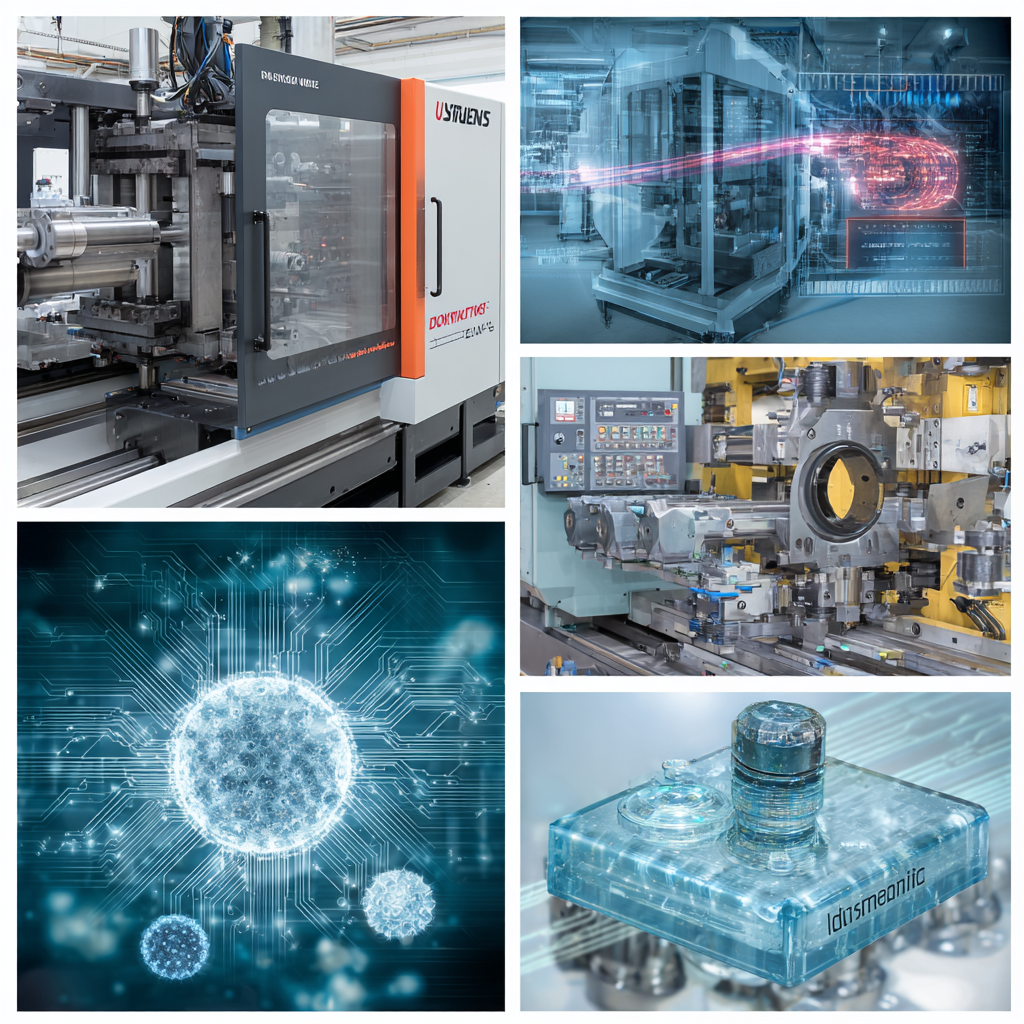

2025 Top 10 Innovations in Injection Moulding Process: Boost Efficiency by 30%+

The injection moulding process has long been a cornerstone of the manufacturing industry, enabling the production of complex shapes with high efficiency and precision. As we look towards 2025, significant advancements in this area promise not only to enhance productivity but also to drive down costs. According to a report by Mordor Intelligence, the global injection moulding market is expected to reach USD 367.46 billion by 2026, growing at a CAGR of 3.5%. This growth reflects an increasing demand for innovative techniques that can streamline operations and minimize waste.

The upcoming decade is poised to be transformative for the injection moulding process, with innovations such as advanced materials, automation, and artificial intelligence set to redefine traditional methodologies. A recent study by the Association for Manufacturing Technology revealed that businesses adopting these innovations could enhance their operational efficiency by over 30%. Such improvements are vital not only for maintaining competitive advantage but also for meeting rising environmental regulations and customer demands for sustainability in manufacturing practices.

As we explore the 2025 top ten innovations in the injection moulding process, it is crucial to understand how these developments will not only alter production methods but also yield quantifiable benefits that align with the industry's future goals of efficiency and sustainability.

Emerging Materials for Injection Moulding: Enhancing Performance and Sustainability

Emerging materials in injection moulding are revolutionizing the industry, enhancing performance while significantly increasing sustainability. Innovative thermoplastics, biopolymers, and composite materials are leading the charge, offering superior mechanical properties and reduced environmental impact. For instance, bio-based plastics derived from renewable resources not only minimize reliance on fossil fuels but also promote a circular economy, where materials can be reused and recycled, thus reducing waste.

Furthermore, advancements in hybrid materials are enabling the production of lightweight and durable parts ideal for industries like automotive and aerospace. These materials not only improve the longevity and functionality of products but also contribute to energy efficiency throughout their life cycle. As manufacturers adopt these emerging materials, they are able to meet stringent regulatory requirements and consumer demands for sustainable practices, ultimately positioning themselves as leaders in a competitive market.

2025 Top 10 Innovations in Injection Moulding Process

This bar chart illustrates the expected efficiency improvements by 2025 for the top 10 innovations in the injection moulding process. Each innovation is measured by its percentage contribution to efficiency gains, highlighting a trend towards sustainability and enhanced performance.

Smart Automation Technologies: Revolutionizing Efficiency in Injection Moulding Operations

The injection moulding industry is on the brink of a significant transformation, driven by advancements in smart automation technologies. According to a recent report by MarketsandMarkets, the global smart manufacturing market is projected to grow from $214 billion in 2022 to over $500 billion by 2027, highlighting the increasing integration of AI and IoT in manufacturing processes. In injection moulding specifically, these technologies enable real-time monitoring and predictive maintenance, leading to a remarkable increase in operational efficiency. Indeed, manufacturers implementing smart automation have reported efficiency gains of up to 30%, significantly reducing cycle times and costs.

The injection moulding industry is on the brink of a significant transformation, driven by advancements in smart automation technologies. According to a recent report by MarketsandMarkets, the global smart manufacturing market is projected to grow from $214 billion in 2022 to over $500 billion by 2027, highlighting the increasing integration of AI and IoT in manufacturing processes. In injection moulding specifically, these technologies enable real-time monitoring and predictive maintenance, leading to a remarkable increase in operational efficiency. Indeed, manufacturers implementing smart automation have reported efficiency gains of up to 30%, significantly reducing cycle times and costs.

Moreover, the introduction of robotic systems and AI algorithms has streamlined production lines by minimizing human error and optimizing resource allocation. A study by McKinsey indicates that companies adopting automation can achieve operational efficiencies of around 20-30%, resulting in enhanced production rates and lower waste generation. The shift towards smart automation not only fosters a more agile production environment but also empowers companies to meet the growing demand for customization and faster delivery times. As injection moulding operations embrace these innovations, they pave the way towards a more efficient and sustainable future in manufacturing.

Data-Driven Decision Making: Leveraging IoT for Real-Time Monitoring and Optimization

In 2025, the injection moulding process is set to experience a significant transformation through the integration of IoT, leading to enhanced operational efficiency. With real-time monitoring capabilities, manufacturers can leverage data-driven decision-making to optimize processes and reduce downtime. A report by McKinsey indicates that companies employing IoT technologies can boost production efficiency by over 30%, primarily by predicting equipment failures before they occur and adjusting workflows dynamically.

**Tip:** Implementing smart sensors can provide immediate feedback on equipment status. This allows for proactive maintenance schedules, ensuring machines operate at peak performance.

Moreover, the synergy between AI and IoT extends beyond simple monitoring. For instance, in urban waste management, IoT systems are utilized to create predictive models for collection schedules, decreasing missed pickups by over 40%. This model can be adapted for injection moulding by using predictive analytics to forecast material usage and optimize inventory management.

**Tip:** Utilize AI-driven predictive analytics to refine your supply chain strategies—this can lead to a reduction in waste and improvements in cost management, enhancing overall productivity in the injection moulding process.

2025 Top 10 Innovations in Injection Moulding Process: Boost Efficiency by 30%+

| Innovation | Description | Efficiency Boost (%) | Implementation Time (months) |

|---|---|---|---|

| Smart Sensors | Integration of IoT sensors for real-time data collection | 35% | 3 |

| Predictive Maintenance | Using AI algorithms to predict machine failure | 30% | 4 |

| Advanced Materials | Utilizing lighter and stronger composite materials | 33% | 6 |

| Energy Recovery Systems | Implementation of systems to recycle energy during processes | 40% | 5 |

| Real-Time Monitoring | Continuous monitoring of production metrics | 32% | 2 |

| Automated Workflow | Streamlining production processes using robotics | 36% | 4 |

| Data Analytics Platforms | Leveraging big data for production optimization | 34% | 3 |

| Flexible Manufacturing Systems | Adapting production lines to varying product types | 31% | 5 |

| Augmented Reality (AR) Training | Using AR for operator training and troubleshooting | 29% | 2 |

| Sustainable Practices | Implementing eco-friendly materials and processes | 30% | 6 |

Advanced Simulation Software: Reducing Cycle Times and Defects by Over 30%

The use of advanced simulation software in the injection moulding process is set to revolutionize the industry by significantly reducing cycle times and defects, with estimates suggesting improvements of over 30%. According to a report by Plastic Technology, companies that have implemented these sophisticated software solutions have reported an average cycle time reduction of approximately 25%, leading to faster production rates and increased output. This enhancement not only boosts productivity but also allows manufacturers to respond more swiftly to market demands.

Furthermore, the impact on defect rates is equally impressive. Research from the Society of Plastics Engineers highlights that the integration of simulation tools can lower defect rates by over 30%, primarily by enabling better process control and predictive analytics. These tools simulate various parameters during the moulding process, allowing engineers to identify potential issues before they occur, thus minimizing waste and improving overall product quality.

As a result, manufacturers who adopt advanced simulation software not only enhance their operational efficiency but also improve their competitive edge in a rapidly evolving market.

Sustainable Practices: Integrating Circular Economy Principles in Injection Moulding Processes

The integration of circular economy principles in injection moulding processes marks a significant shift towards sustainability in manufacturing. By prioritizing recycling and reusing materials, companies can minimize waste and reduce their overall environmental impact. This not only helps in conserving resources but also reduces energy consumption throughout the production cycle. Innovations such as using biodegradable polymers and incorporating recycled plastics into the moulding process are essential steps that manufacturers can adopt to enhance sustainability.

Furthermore, adopting sustainable practices within injection moulding can lead to significant cost savings and increased operational efficiency. Techniques like material flow optimization, energy-efficient machinery, and waste heat recovery can boost the performance of production lines, potentially increasing efficiency by over 30%. By embracing a sustainable approach and circular economy principles, manufacturers not only contribute to environmental conservation but also position themselves as leaders in a competitive market that increasingly values eco-friendly practices.

Related Posts

-

What is Poly Plastic and How it Revolutionizes Packaging Solutions in 2023

-

10 Best PVC Material Products for Durable Home and Garden Solutions

-

Exploring Innovative Uses for Plastic Caps: From DIY Crafts to Sustainable Solutions

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs

-

Exploring the Versatility and Applications of PVC Film in Modern Industries