Unlocking Innovation: The Future of Design for Injection Molding in 2025

As we approach 2025, the realm of design for injection molding is poised for transformative changes that will redefine the standards of efficiency, sustainability, and creativity within the manufacturing industry. With rapid advancements in technology, especially in areas such as automation, materials science, and computer-aided design, innovative methodologies are emerging that enhance the design process, streamline production, and reduce environmental impact. This evolution requires designers and engineers to re-evaluate traditional practices and embrace new strategies that not only accommodate the complexities of modern products but also align with the expectations of eco-conscious consumers.

The future of design for injection molding will likely incorporate intelligent design principles, where the use of data analytics and machine learning streamlines production processes and optimizes designs for both functionality and manufacturability. Moreover, the integration of advanced materials will expand the possibilities for creating more durable, lightweight, and sustainable parts. As we explore the “2025 How to” genres related to injection molding, it becomes evident that a proactive approach towards innovation and collaboration will empower industry players to overcome challenges and seize opportunities, leading to a new era of design excellence.

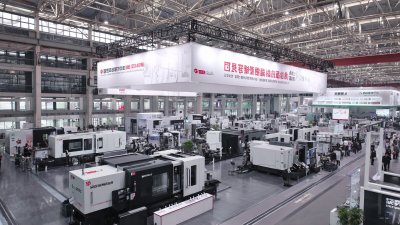

Exploring Emerging Technologies in Injection Molding Design for 2025

The landscape of injection molding design is set to undergo transformative changes by 2025, driven by the adoption of emerging technologies. Reports indicate that the global market for injection molding is anticipated to reach approximately $420 billion by 2025, highlighting the increasing demand for efficiency and innovation. One of the pivotal technologies contributing to this growth is Industry 4.0, which integrates automation, data exchange, and smart manufacturing into the injection molding process. This incorporation not only enhances productivity but also promotes real-time decision-making, significantly reducing lead times and operational costs.

In addition to Industry 4.0, advancements in materials science are poised to revolutionize injection molding design. For instance, the development of biodegradable plastics and high-performance polymers can lead to more sustainable production methods and enhanced product qualities. A recent study projected that the use of advanced materials in injection molding could reduce material waste by up to 30% by 2025. As manufacturers seek to minimize their environmental footprint while achieving superior performance, the combination of smart technologies and innovative materials will be crucial for staying competitive in the evolving market.

Integrating Sustainability into Injection Molding Practices

The future of injection molding is increasingly intertwined with sustainable practices, as the industry seeks to reduce its environmental footprint amidst growing ecological concerns. According to a report by Grand View Research, the global injection molding market is projected to reach approximately $380 billion by 2025, driven by innovations that prioritize recyclability and resource efficiency. Companies are now embracing bioplastics and other eco-friendly materials, which not only preserve the quality of molded products but also minimize reliance on fossil fuels.

Furthermore, a significant shift towards energy-efficient machinery is taking place within the industry. A study published by the Plastics Industry Association highlights that advanced injection molding machines can reduce energy consumption by up to 70% compared to conventional systems. The integration of smart technology and automation in these machines not only enhances production efficiency but also contributes to a more sustainable manufacturing process by lowering waste generation and improving material utilization. As these innovations unfold, the injection molding sector is poised to lead the way in sustainable practices, fostering an eco-conscious approach while meeting the demands of a rapidly evolving market.

Harnessing AI and Automation to Enhance Design Efficiency

As we look towards 2025, the integration of AI and automation into the design process for injection molding is set to revolutionize the industry. Recent reports highlight that over 75% of full-time employees are now utilizing generative AI in their work, a significant increase that underscores the technology's role in enhancing design efficiency across various sectors. In the realm of manufacturing, AI is not just a support tool; it is a catalyst that shortens design cycles and improves overall workflow management.

The pharmaceutical industry showcases the transformative power of AI, where drug development timelines have been slashed from 10-15 years to just 3-5 years thanks to AI's capabilities. Target identification speeds have soared by 100 times, and optimization efficiencies have increased by 30%, dramatically impacting how innovations are brought to market.

Similarly, in injection molding design, AI can streamline complex processes, reduce material waste, and enhance the accuracy of prototypes. As companies continue to embrace these technologies, the potential for improved efficiency and innovation becomes apparent, paving the way for a new era in manufacturing.

Adapting to Market Trends: Consumer Needs and Injection Molding Innovations

The landscape of injection molding is poised for significant transformation by 2025, driven primarily by the evolving needs of consumers. As preferences shift towards sustainability and customization, the industry is responding with innovative technologies that not only meet these demands but also enhance efficiency. Techniques such as additive manufacturing are becoming increasingly integral, allowing for shorter production cycles and the capability to create unique, tailor-made products that appeal to individual consumer preferences.

Moreover, advancements in materials science are unlocking new possibilities, with bio-based and recycled materials gaining traction in production lines. This shift is not only environmentally conscious but also caters to the burgeoning market of eco-aware consumers. Companies that successfully integrate these innovations will not only satisfy current market trends but also carve out new niches for growth, positioning themselves as leaders in a rapidly evolving industrial landscape.

As we move towards 2025, adaptation to these market trends will be crucial for the survival and competitiveness of businesses in the injection molding sector.

Collaborative Design Approaches: Fostering Innovation in Molding Techniques

In the rapidly evolving landscape of injection molding, the emphasis on collaborative design approaches is proving to be a catalyst for innovation. According to a report by BCC Research, the global injection molding market is projected to reach $367.5 billion by 2025, driven by advancements in technology and the increasing demand for custom and complex designs. This underscores the necessity for manufacturers to embrace collaborative strategies that leverage cross-disciplinary expertise. By integrating feedback from designers, engineers, and manufacturers early in the design process, teams can create more efficient and innovative molding techniques that reduce lead times and costs.

Moreover, fostering collaboration allows for the exploration of new materials and sustainable practices that are becoming crucial in today's market. A study by the American Injection Molding Institute indicated that 70% of professionals believe that innovative design processes significantly enhance product performance while minimizing environmental impact. As companies initiate partnerships with research institutions and invest in collaborative platforms, they are not only improving product quality but are also enhancing their adaptability to market changes. This shift towards a collaborative mindset is setting the pace for what the future of injection molding will hold, driving forward the innovation necessary to meet emerging industry challenges.

Unlocking Innovation: The Future of Design for Injection Molding in 2025

| Technique | Description | Collaborative Aspect | Expected Impact |

|---|---|---|---|

| Generative Design | Utilizes algorithms to generate optimal designs based on specified constraints. | Enhanced teamwork by engaging engineers and designers in the design process. | Increased design efficiency and material savings. |

| 3D Printing Integration | Incorporates 3D printed molds for rapid prototyping and testing. | Facilitates cross-department collaboration for quicker feedback loops. | Shorter production times and improved design validation. |

| Smart Manufacturing | Utilizes IoT and data analytics for real-time monitoring and adjustments. | Encourages collaboration between IT and manufacturing teams for system optimization. | Improved process efficiency and reduced waste. |

| Sustainable Materials | Focus on using biodegradable and recycled materials for injection molding. | Collaboration with suppliers and researchers to innovate material choices. | Positive environmental impact and enhanced brand reputation. |

| Simulation Software | Advanced tools for simulating injection molding processes before production. | Engages design and production teams early in the development process. | Reduced development costs and minimized production errors. |

Related Posts

-

Innovative Techniques for Optimizing Design for Injection Molding in Modern Manufacturing

-

Discovering the Secrets of Low Cost Injection Molding for Beginners

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Exploring the Future of Plastic Angle Products at the 138th Canton Fair 2025 in China

-

Envisioning Tomorrow: The Role of Polypropylene Plastic in Sustainable Manufacturing

-

Ultimate Checklist for Selecting the Right Plastic Profiles for Your Projects